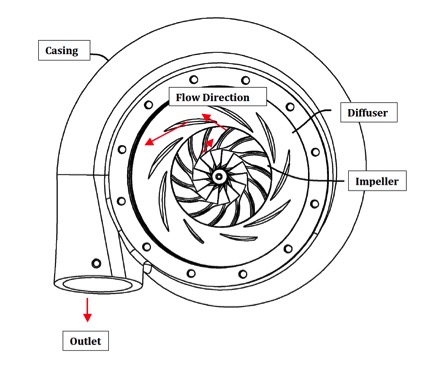

Nearly every industrial application, from a simple car repair shop or a complex maintenance system to a multi-structure manufacturing plant has some sort of compressed air framework. In most applications at public works or government facilities, the compressed air system is so critical that the site cannot function without it.

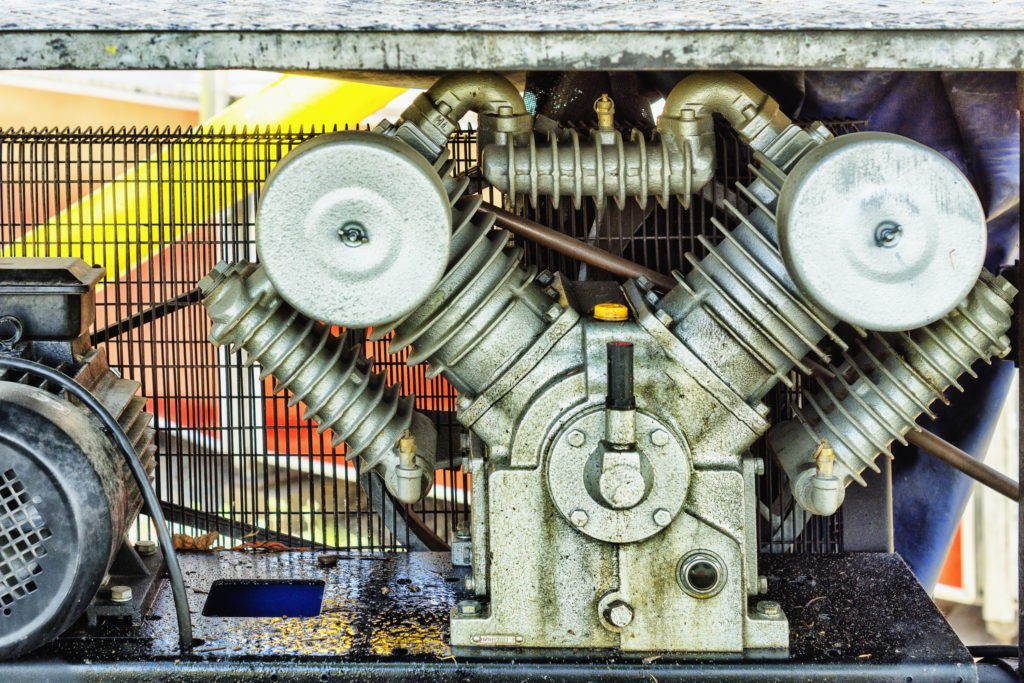

Air compressor systems vary in side from small units to massive systems of over 50,000 horsepower. These air compressors’ power consumption usually exceeds that of any any other type of machine. As such, running an inefficient compressed air system can increase the cost of production drastically.

Using modern systems that employ the latest technologies can help deliver energy savings of 20 to 50% or even more. For government agencies, this is equivalent to tens or even hundreds of thousands of dollars of yearly savings potential dependent on the use; funds that can be diverted to another state project.

A properly used compressed air system can reduce energy consumption, increase production limits, reduce maintenance, improve product quantity and quality, and decrease overall downtime. Proper management involves:

Preventative Maintenance

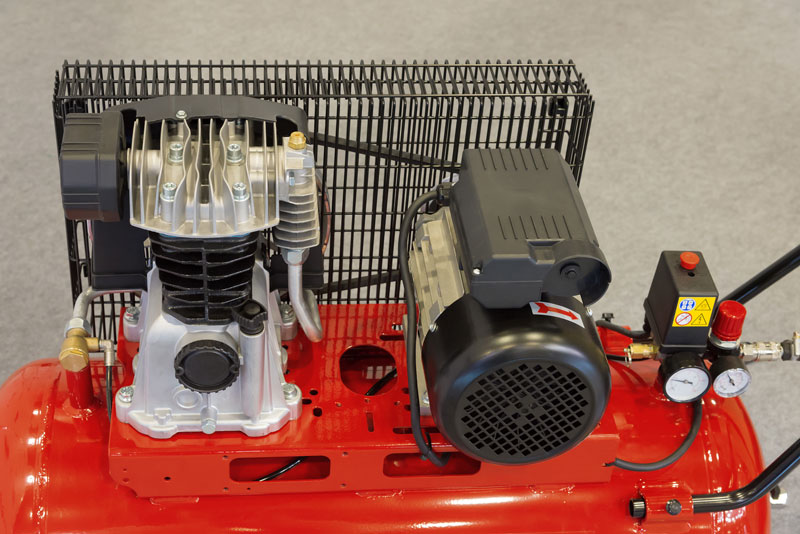

Scheduled preventative maintenance on the components of your industrial air compressor system is key – ensuring optimal performance, maintaining equipment reliability, keeping the warranties in effect, and maximizing your return on investment. Conversely, neglecting routine maintenance increases the risk of expensive breakdowns, extended downtime and reduced production, and shorter life expectancy of your equipment.

Repairs and Overhauls

It is important to form good relationships with service and repair companies that specialize in the maintenance of most of the major brands of industrial compressed air systems of varying horsepower. The process involves a skilled and experienced technician examining your air compressor to identify any major faults of causes of malfunction, ordering the necessary parts, and performing repairs on-site.

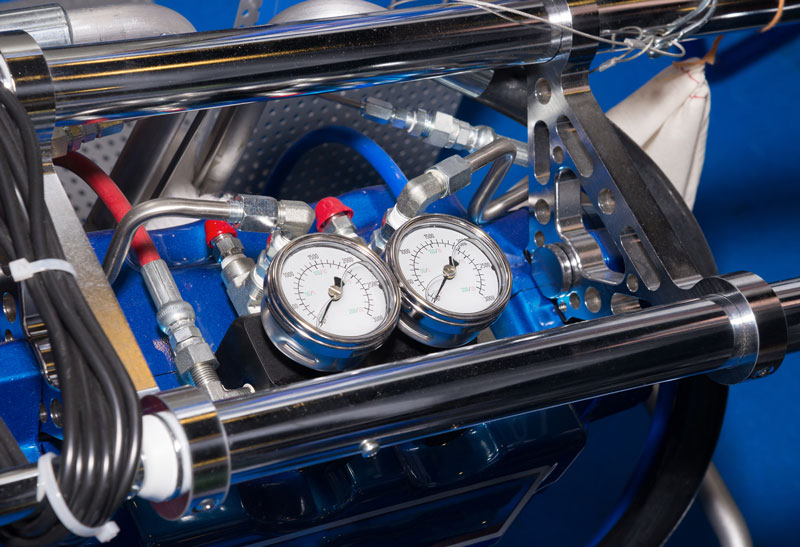

Energy Audit from Q Air-California

If you are not sure about the (in)efficiency of your air compressor system, you should request an energy audit to evaluate the need for an upgrade.