By David Grabau, Ingersoll Rand Compression Technologies and Services

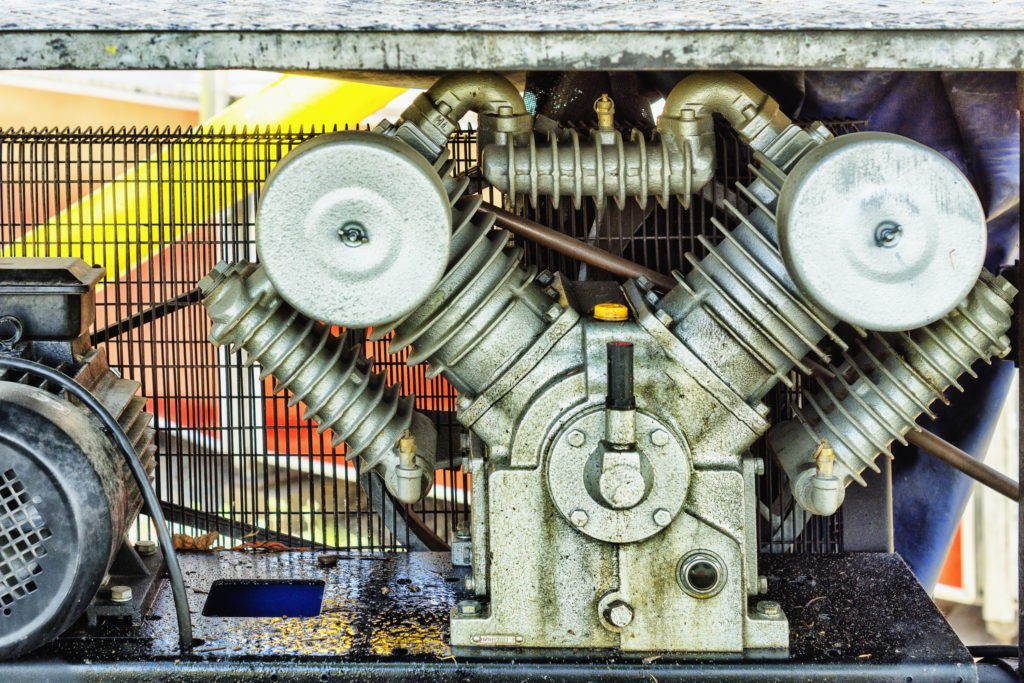

When an air compressor needs to be overhauled, you hope the experience will be as pain free as possible. There are different approaches to overhauling an air compressor, and each has different implications related to cost, parts, service and performance.

How to Know When it’s Time to Overhaul an Air Compressor

Knowing when to overhaul a unit is important, and there are certain signs that indicate a unit needs attention. Performing routine fluid checks, taking oil samples, and routinely checking for bearing vibration can unveil indicators that suggest an upcoming failure. Oil contamination with metal fragments usually indicates parts are wearing. It’s also important to take notice of airend temperature increases. If internal compressor temperatures go up, that’s a good indicator that the cooler may be failing.

Two Overhaul Options: Remanufacture or Rebuild

The rebuild approach to overhauling an air compressor typically takes place in the field, at the customer site, where the compressor is already installed. The product testing after the rebuild occurs in the field and may include checking discharge pressure, vibration levels and testing for oil leaks. During a non-OEM rebuild, existing parts are either refurbished or replaced with rebuilt or third-party parts.

A remanufactured air compressor is overhauled within the original equipment manufacturer’s (OEM) factory. In this scenario, the factory will have all of the design drawings and specifications to bring the unit back to the original factory specifications. The manufacturer may also build the replacement airend with in-house parts, replacing bearings, seals, gaskets, pumps and more with new or OEM-certified parts. They will also conduct a complete mechanical and performance test before the unit leaves the factory.