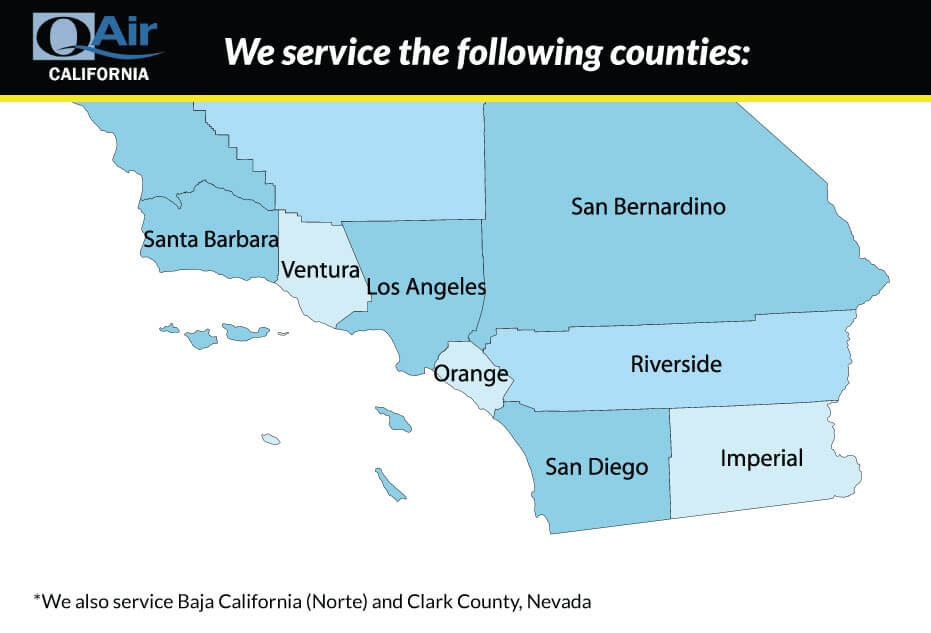

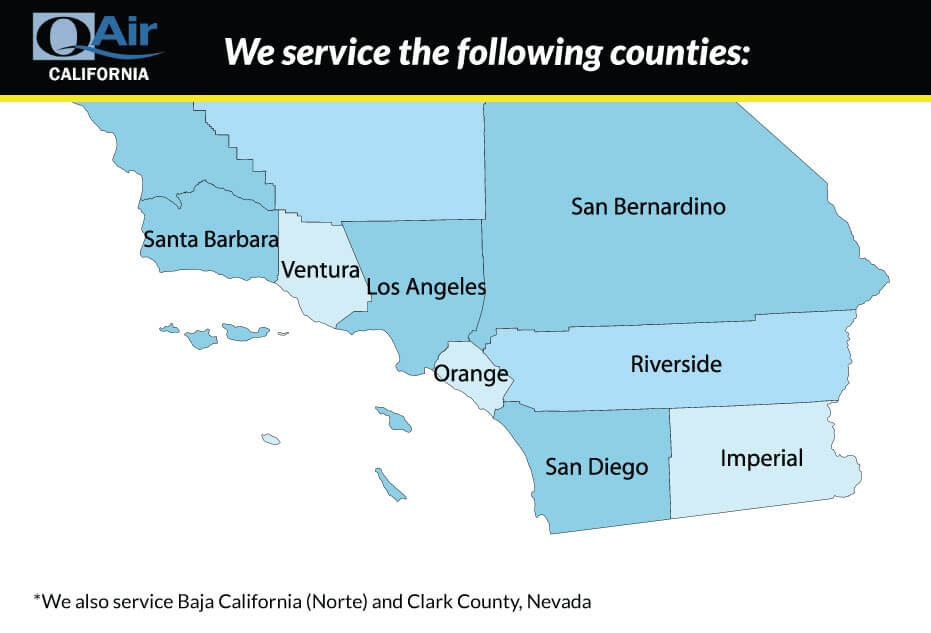

Q Air-California can implement your audit recommendations in Santa Fe Springs, CA. We have the capacity & resources to implement all of the recommendations provided in your thorough comprehensive analysis, which separates us from the many other companies that provide only auditing services.

“I received an audit from another company, can you help?”

Absolutely! If you have already received a thorough, comprehensive audit of your energy efficiency then we can help implement all of the recommendations provided. However, we may see other recommendations that may not have been initially provided.

Q Air-California can offer 5 levels of technical services to meet the individual needs of the customer. From the basic compressed air system walk-through to the full system audit and leak detection, our goal is always the same – help the customer to save money by providing equipment and services that produce the best results.

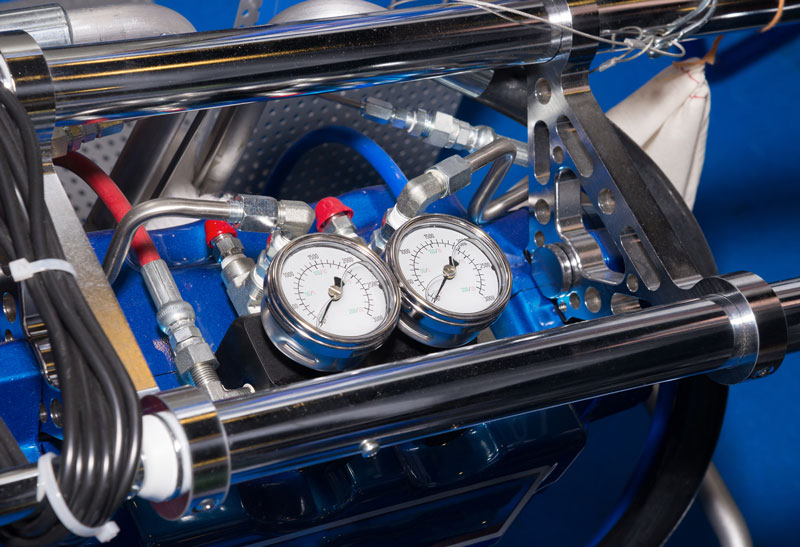

Starting with the supply side of the system, our specialists utilize high speed data loggers recorded in real time system parameters such as pressure, flow, kilowatts, amperage, dew point and air quality, depending upon customer requirements. You can count on us to provide a thorough and definitive compressed air energy audit that not only identifies areas of concern, but also gives a complete turnkey solution with ROI analysis.

Information collected during the monitoring period is analyzed and included along with a comprehensive report which includes the following information:

- Current System Operating Costs

- Complete Supply Side System Analysis

- Areas of Opportunity on the Demand Side

- Potential Energy & Cost Savings

- Turnkey Corrective Actions with ROI Analysis

- Supporting Recorded Data

- Possible Energy Rebate Programs

Call us @ 888.311.7247 to see if you qualify.

Do You Qualify?

We have provided a document below to help determine whether or not you qualify.

Download Q Air-California Jobsite Worksheet

No two compressed air systems are alike, and it takes an experienced auditor to effectively assess and identify areas of improvement. This is not a simple matter of connecting a black box to record data and spit out a summary report that says buy the biggest VFD compressor. In fact, depending on the complexity of the compressed air system, it requires the measurement of various power, pressure, and flow components over time and the ability to accurately analyze the data with the best software in the industry. Our objective is to provide the expert assistance needed to maximize system performance, lower operating costs, and increasing system reliability.