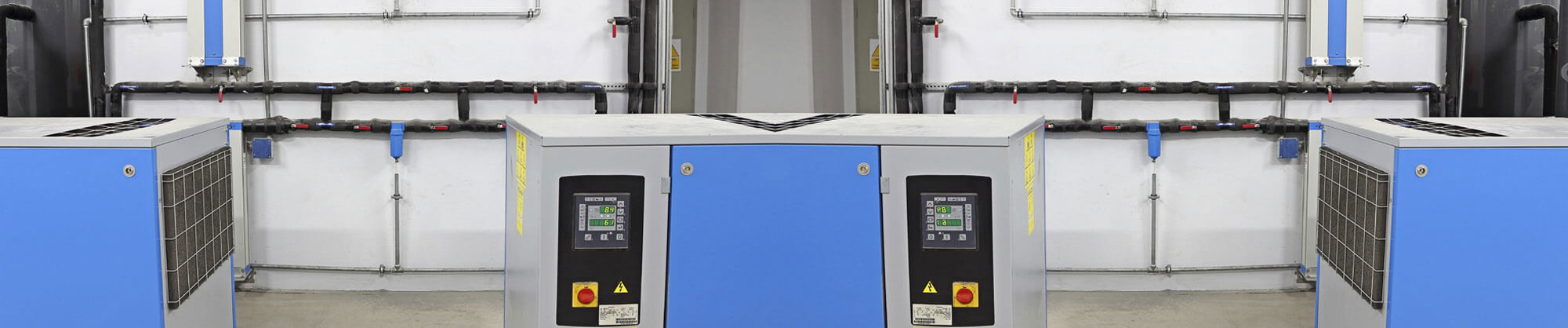

There are also many different types of industrial air compressors to suit the needs of each specific application. At Q Air-California, we provide industrial air compressor installation, maintenance, and repair services, as well as energy audits for the different kinds of air compressors.

Industrial air compressors are not not only found in manufacturing and processing plants, but also in power plants, constructions, automobile plants, welding shops, painting shops, ships, and many other places.

Types of Air Compressors Based On Mode of Operation

Industrial air compressors are classified based on the mode of operation, with the two most common categories being:

- Positive displacement - include reciprocating and rotary air compressors

- Roto-dynamic air compressors

Reciprocating air compressors can be further categorized into:

- In-line compressors

- Diaphragm compressors

- Single-acting air compressors

- Double-acting air compressors

- “V”-shaped air compressors

- Tandem Piston compressors

Rotary air compressors can also be further divided into:

- Vane type air compressors

- Screw compressors

- Lobe and scroll compressors

- Many more

There are also different kinds of roto-dynamic compressors, including:

- Centrifugal air compressors

- Axial flow air compressors

Other Air Compressor Features

When buying an industrial air compressor, your decision may also be influenced by other factors, such as:

- The number of air compression stages, such as single-stage, multi-stage, 2-stage

- The cooling medium - oil-cooled, water cooled, or air-cooled

- Type of drive - belt, chain, turbine, motor, engine, direct-coupling, or gear

- Method of lubrication - oil-free, splash, or forced lubrication

- Service pressure - low, high, or medium

The Right Industrial Air Compressor for Your Job

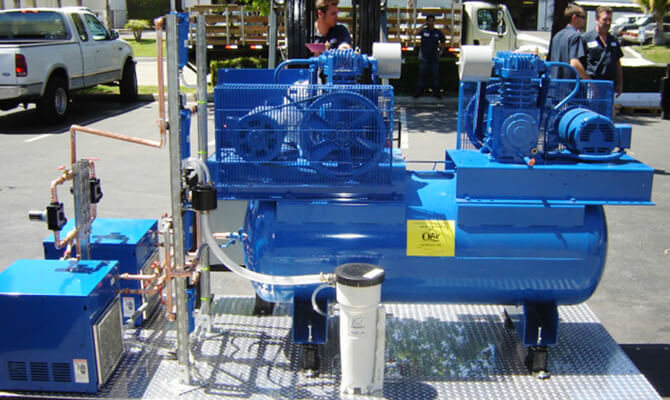

When choosing a compressor, you should first determine what you plan on using it for. Consider whether you need compressed air for specialized applications. How much air do you need? You can calculate this in cubic feet per minute by checking the tools or equipment specifications you intend to use the compressed air on.

With that in mind, here is a simple guide to steer you in the right direction:

- Reciprocating piston compressors are mostly used for high-pressure/low-velocity applications (under 30 bars). This is sufficient for most general-purpose applications, like providing compressed air in a workshop for cleaning dust, hand-tools, or small paint jobs.

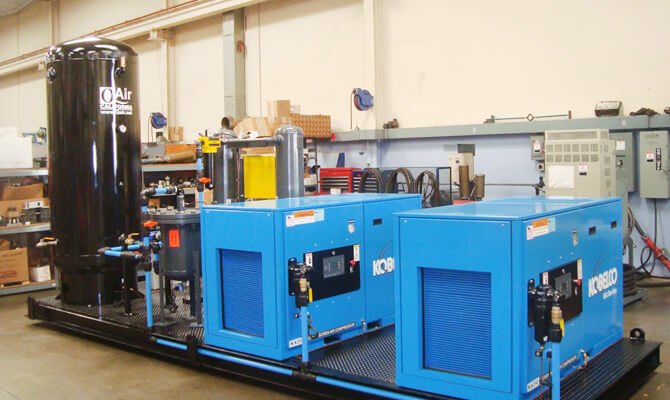

- Rotary screw compressors are typically used for continuous applications with high velocity/low-pressure (7/8 bar)

- Oil-free rotary screw compressors are ideal for applications that require absolutely no contact with oil. Otherwise, you should consider the more cost-effective oil-injected type

- Oil-injected rotary screw compressors have better energy efficiency than piston-type compressors. They also have low noise level, and deliver vast amounts of compressed air at fairly low exit temperature.

- Scroll air compressors are ideal for silent, smooth delivery of compressed air. They have no vibrations, and are mostly used for applications that need small amounts of clean, oil-free compressed air, such as laboratories, specialized factories, or drinking water-treatment facilities. However, the output volume is quite lower compared to an oil-free rotary screw compressor.

We Can Help You Narrow Down Your Options

The range of industrial air compressors is growing continuously. With an abundance of choices, you will need the assistance of professionals like Q Air-California to help you select the best air compressor for your application. Our engineers will also help you to create a maintenance schedule to ensure optimal performance and longevity of the equipment.