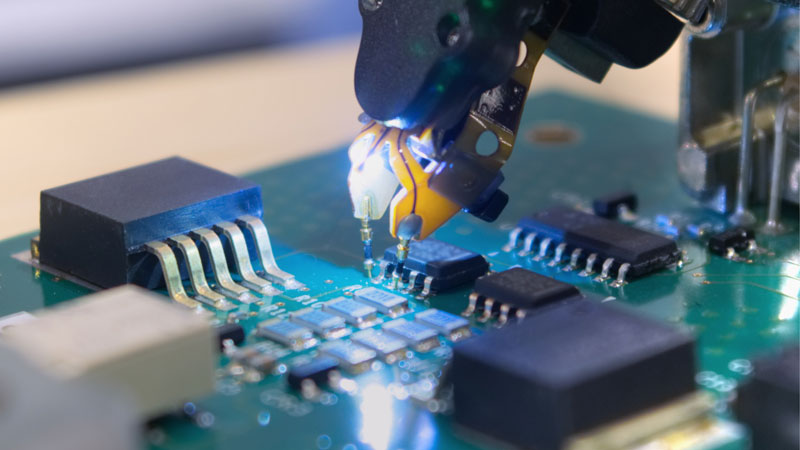

An industry like electronics and semiconductor manufacturing requires technology that completely eliminates the risk of contamination – oil, water, particles – and the dire consequences that may follow, such as production downtime, unspoiled or unsafe products, costly product recalls, and legal issues that can destroy your brand image.

For such applications where the air quality is important for the production process and end-product, industries prefer to use oil-free compressed air systems. Only oil-free air compressors can deliver 100% uncontaminated air.

Challenges of Oil-Injected Compressors

High quality oil-injected compressors can deliver oil-free air, thanks to the integrated oil removal filters. However, there have been a few cases in the past where these compressors have resulted in oil contamination, despite having several stages of oil removal. With oil-injected compressors, there is always the risk of contamination and the likelihood of severe consequences for your production process and the end product.

One of the biggest factor affecting the efficiency of oil-based compressor systems and the purity of the compressed air output is temperature. When the air passes through the oil removal filters, the oil carryover via the filter media increases significantly according to the temperature at the filtration interface.

Moreover, higher temperatures translate to higher vapor content of the air, as well as decreased lifetime of activated carbon filters. In fact, with the stated changes in temperature, from 20°C (68°F) to 40°C (104°F), the lifetime of the filter can be drastically reduced from 1000 hours to just 50 hours. This means that you may need to change your filters 2-3 times a week, failure to which it could allow oil to pass.

Also keep in mind that ambient air has minute traces of oil coming vehicle exhaust and industrial sources. However, in highly contaminated areas, the oil content rarely exceeds 0.003 mg per cubic meter. This result is based on a test conducted near a factory with substantial machining activity, including milling, drilling, grinding, and turning, plus there was heavy vehicular traffic and a garbage incinerator around the location.

Cost Implications of Oil-Free Compressors

Although the initial cost of oil-free compressors is high, you achieve greater savings in the long run by eliminating costs associated with replacing expensive filters, reducing service and maintenance costs due to treating oily condensate, and avoiding the costs of extra energy required to compensate for pressure drops in filters.